Company Profile

Patil Automation Limited is a Pune-based industrial automation firm established in 2015, specializing in the design, manufacture, and installation of advanced automation systems. Catering primarily to sectors like automotive, engineering, and manufacturing, the company offers bespoke solutions including robotic welding lines, material handling systems, assembly fixtures, testing and inspection equipment, and related repair and maintenance services.

The company has filed its Draft Red Herring Prospectus (DRHP) for an SME IPO on NSE Emerge via the book-building route. The proposed issue size is up to 5.8 million equity shares of face value ₹10 each, including a reserved portion for market makers. Exact price band and offer size are yet to be announced.

Business Model

Patil Automation Limited operates on a project-based, solution-oriented business model focused on delivering customized industrial automation systems. The company designs, manufactures, installs, and maintains automation equipment tailored to specific client needs—mainly in the automotive, engineering, and manufacturing sectors.

🔧 Key Elements of the Business Model:

- End-to-End Solutions

Patil offers turnkey automation systems including robotic welding lines, material handling setups, assembly stations, and testing equipment. It provides services from design to installation and post-deployment maintenance. - Customization and Engineering Expertise

Every project is engineered according to the customer’s technical requirements. This specialization allows the company to serve high-precision segments like automotive OEMs and tier-1 suppliers. - In-House Manufacturing

The company maintains its own production facility where it fabricates key components. This ensures quality control, reduces lead times, and allows for faster customization. - After-Sales Support

Patil Automation ensures long-term client engagement through maintenance contracts, repair services, and system upgrades, which also serve as recurring revenue channels. - Client-Centric Revenue Model

Revenue is generated through project-based billing, milestone payments, and service charges. Each automation project is priced based on scope, complexity, and installation requirements.

Product Portfolio

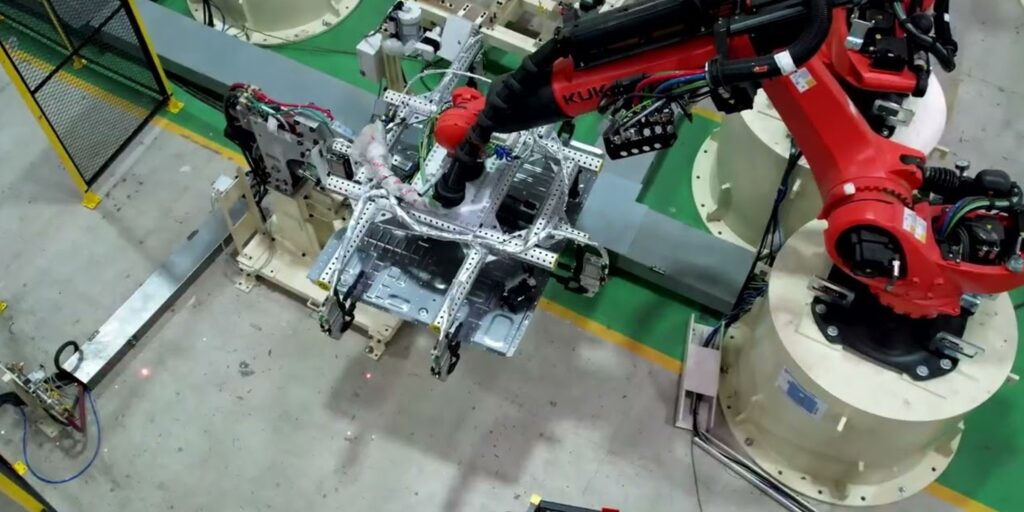

- Robotic Welding & Assembly Systems

Custom robotic welding cells (spot, MIG, TIG) and assembly lines designed for automotive and manufacturing clients requiring precision and high throughput. - Material Handling Equipment

Turnkey solutions including conveyors, robotic pick-and-place units, and automated transfer stations engineered to enhance production flow and reduce manual handling. - Testing & Inspection Systems

Integration of inline testing stations, quality inspection lines, and measurement automation to ensure product compliance and production accuracy. - Auxiliary Fixtures & Tooling

Design and fabrication of jigs, fixtures, welding tables, and tooling solutions to support precise manufacturing and smooth workflow integration. - After-Sales Services & Support

Comprehensive maintenance, retrofitting, system calibration, and upgrade offerings to extend equipment life and optimize performance post-installation.

Features Across Products

- Customization & Flexibility

All automation systems are designed to meet the specific operational and spatial requirements of each client, ensuring seamless integration with existing workflows. - High Precision & Reliability

Use of advanced robotics, motion control, and sensor technology ensures accuracy, repeatability, and consistent performance across production cycles. - Energy Efficiency

Products are engineered to optimize power consumption through smart automation logic, efficient motors, and minimal idle-time design. - Scalability & Modularity

Systems are built with modular components that allow future expansion or integration with new technologies without complete overhauls. - User-Friendly Interfaces

Touchscreen HMIs (Human Machine Interfaces), diagnostic dashboards, and intuitive software controls make operations easier and reduce operator training time. - Safety and Compliance

All systems are equipped with robust safety mechanisms such as emergency stops, interlocks, and comply with industrial safety standards. - After-Sales Support Readiness

All products are designed with diagnostics and remote support features to facilitate quick troubleshooting and preventive maintenance.

🎯 Objectives of the IPO

Set Up an In-House Manufacturing Facility

The company plans to invest in land and plant equipment to establish its own facility, enabling higher production capacity for automation systems.

Repay Existing Borrowings

Funds will help reduce debt liabilities, improving the company’s financial stability and lowering finance costs.

Boost Working Capital

A portion of the proceeds is earmarked to enhance liquidity, supporting inventory needs, material procurement, and seamless project execution.

Technology and Tooling Enhancement

Investment in modern machinery, automation technologies, and software tools will increase efficiency and precision in system development.

General Corporate Purposes

The remaining funds will be used for growth initiatives, marketing efforts, administrative support, and other strategic activities aimed at business expansion.

Future Outlook

Patil Automation Limited is well-positioned for growth as India’s manufacturing sector increasingly embraces automation, robotics, and smart production systems. Focused on precision engineering and custom automation, the company stands to benefit from rising demand in industries such as automotive, electric vehicles, electronics, and white goods.

With planned investment in in-house manufacturing capabilities and advanced tools, Patil aims to enhance its execution capacity, reduce lead times, and improve operational efficiency. The introduction of an in-house facility is expected to support larger project volumes and attract mid-sized enterprises seeking turnkey automation solutions.

As clients prioritize productivity, quality, and cost efficiency, Patil’s ability to deliver engineered solutions with after-sales support and upgrade services is expected to open up substantial recurring revenue opportunities. Over the next few years, Patil intends to deepen its relationships with OEMs and engineering firms, expand its geographic footprint across India, and explore adjacent sectors such as warehousing, logistics, and automated testing solutions.

🧭 Vision and Leadership

🌟 Vision

Patil Automation Limited envisions becoming a trusted innovation partner for industries seeking world-class automation, precision, and efficiency. The company aims to empower Indian and global manufacturers with cutting-edge technologies that drive productivity, reduce manual intervention, and support smart factory transformation.

Its long-term goal is to lead India’s transition toward Industry 4.0, delivering intelligent automation systems that are scalable, sustainable, and globally competitive.

👨💼 Leadership

The company is led by a technically driven and entrepreneurially focused leadership team with deep expertise in industrial automation, engineering design, and manufacturing execution. The founders and senior management have years of experience working with OEMs and industrial clients, enabling them to understand complex production challenges and deliver tailor-made solutions.

Leadership at Patil Automation emphasizes:

- Innovation through in-house R&D

- Customer-first approach

- Sustainable growth

- Workforce skill development

- Strategic partnerships

Their forward-thinking mindset has positioned the company as a rising force in India’s automation ecosystem.

Market Positioning and Growth Prospects

📍 Market Positioning

Patil Automation Limited has positioned itself as a specialized automation partner for Indian manufacturers seeking reliable, custom-built solutions. By focusing on turnkey robotic systems, material handling solutions, and automated testing platforms, the company caters to key verticals such as automotive, engineering, and white goods manufacturing.

Its strength lies in delivering highly engineered, end-to-end systems—from concept to commissioning—offering seamless integration with existing production lines. This niche focus has earned Patil credibility among OEMs and Tier-1 suppliers, particularly in western and southern India.

🚀 Growth Prospects

- Rising Demand for Automation in Manufacturing

With Indian industries pushing for higher efficiency, consistency, and productivity, automation adoption is growing rapidly—opening long-term opportunities for solution providers like Patil. - Government Push for ‘Make in India’ and Industry 4.0

Government initiatives supporting domestic manufacturing and digitization further strengthen the market for companies offering smart factory and automation solutions. - EV and Auto Sector Expansion

As the electric vehicle (EV) segment grows, demand for precision assembly, testing, and welding automation will rise—where Patil already has proven capabilities. - Geographic and Sectoral Diversification

Patil plans to expand beyond the automotive segment into logistics, consumer appliances, and electronics, tapping into broader industrial automation demand. - Capacity Expansion via IPO Proceeds

Funds raised will be utilized to establish in-house facilities, improve project turnaround times, and enable larger-scale operations—fueling future growth.